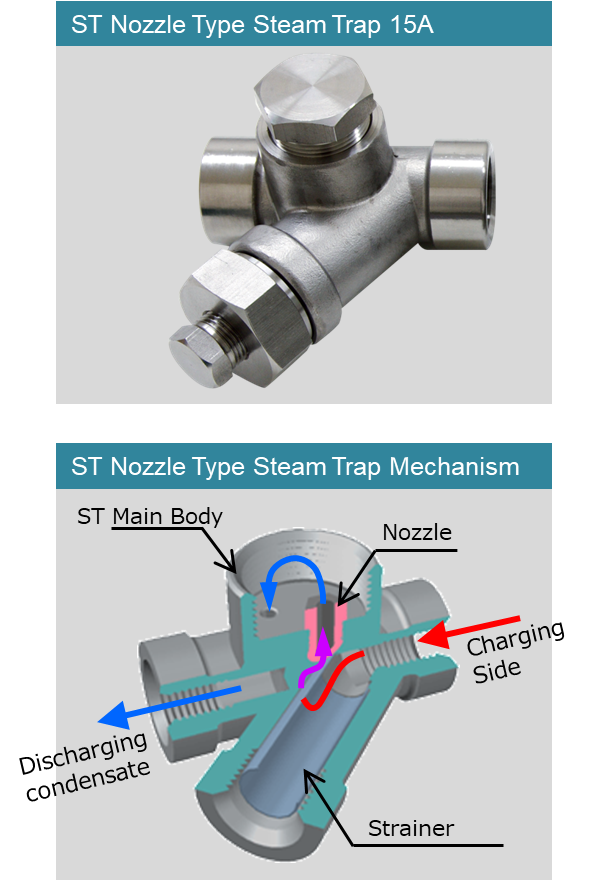

What is a “ST Nozzle Type Steam Trap”?

Benefits of ST Nozzle Type Steam Trap

Benefits

- Allows adjustment and tuning by changing nozzle

- Accommodate various flow volume with variety of nozzle types

- Integrated with the Operational Logic that brings the least steam leakage

- Minimize changes in pressure

- Superior tolerance

- Simple maintenance

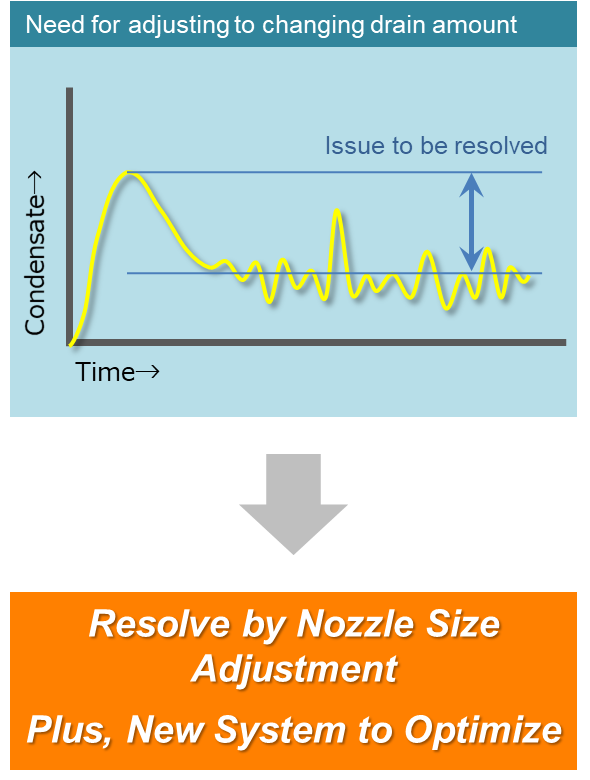

An Issue in ST Nozzle Type Steam Trap and its Solution

Issue

Does not adjust to changes in condensate amount and in pressure

Solution

- When the pipe cubic volume is sufficient for changes in drain amount, constant discharge of average drain is

- Apply 2-3 count larger nozzle, as the resulting leakage is much less than that of using Mechanical

- (3) Employ the proposed System Approach for compulsory discharge via by-path

Principle of ST Nozzle Type Steam Trap

(1)Constantly and appropriately discharged through nozzle holes

(2)When drain amount is less, condensate is depressurized while running through narrow nozzle holes, transforming into flash steam and its cubic mass protect steam from leaking out

(3)Even if drain is minimal, steam leakage is minimal, as the nozzle holes are so narrow, steam density being 1/1700 of water and the kinetic viscosity if 73 times that of water

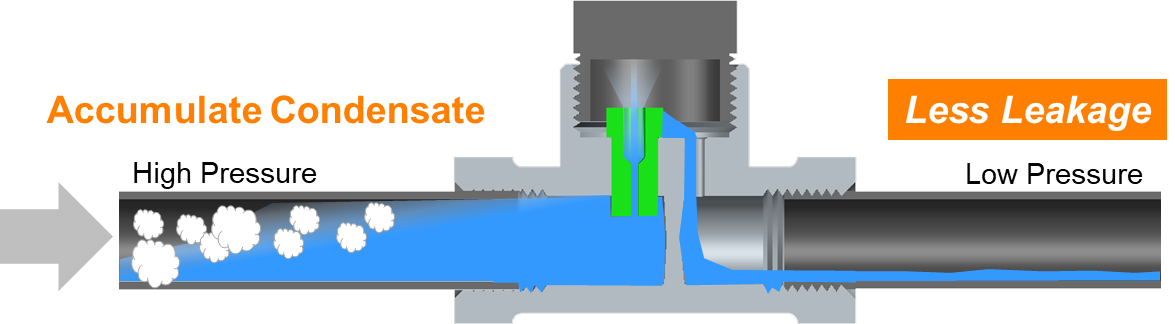

Unique ST Nozzle Typeʼs Operational Logic to Optimize

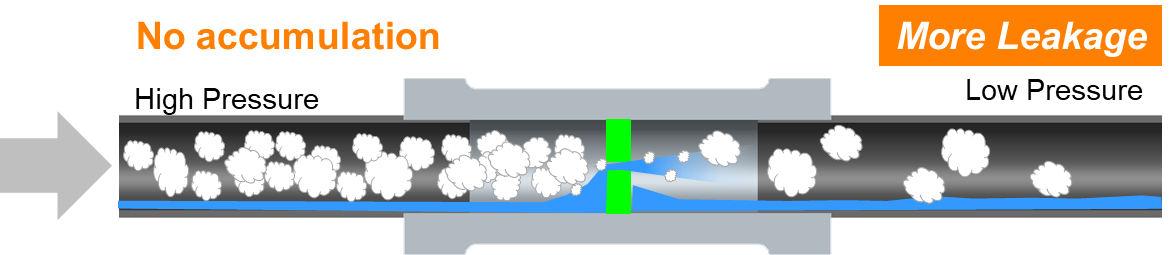

The key for optimizing is to appropriately “accumulate condensate”

Appropriate accumulation of drain at the pre-nozzle stage minimizes leakage The nozzle variety and empirical analysis of ST enables optimization

Non- ST Nozzle Type Steam Traps donʼt accumulate drain

Orifice/Nozzle traps of other manufacturers are not designed to accumulate condensate

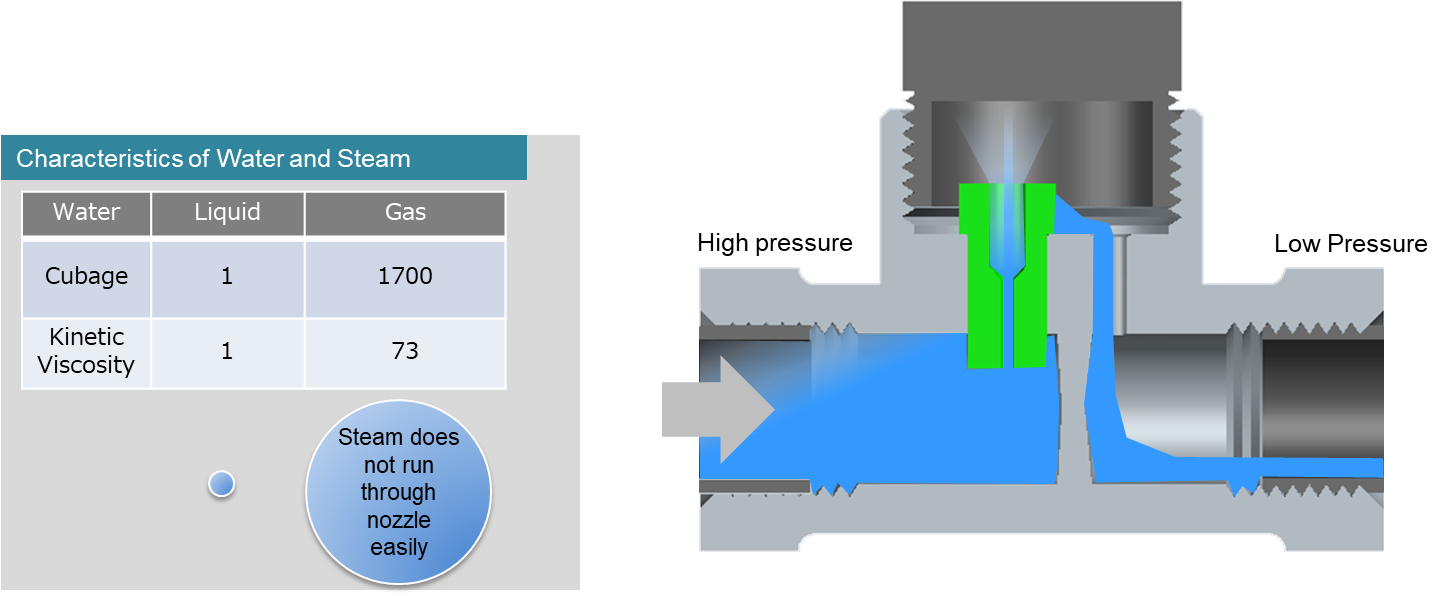

Theoretical Backgrounds of ST Nozzle Type Steam Trap

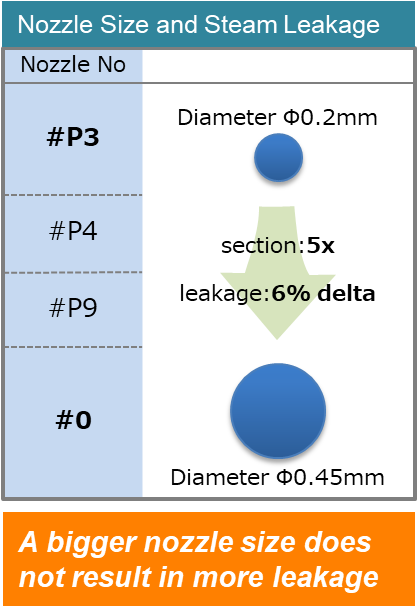

And therefore a discharge amount will be 5.06 times larger, if other things being equal

When condensate is discharge for 1 min, the remaining 4.06min is for discharging steam

However, as the specific gravity of steam is 1/1700, and the kinetic viscosity is about 1/70, the mass of steam in this 4.06min will be1/70,

and therefore:

1+(4.06/70)=1.06

The steam leakage is 6%

Even though a bigger nozzle with 5 times larger cross section area is employed, a significant leakage saving can be achieved as compare with Intermittent traps

ST Nozzle Type Steam Trap: Easy Tuning by Changing Nozzles

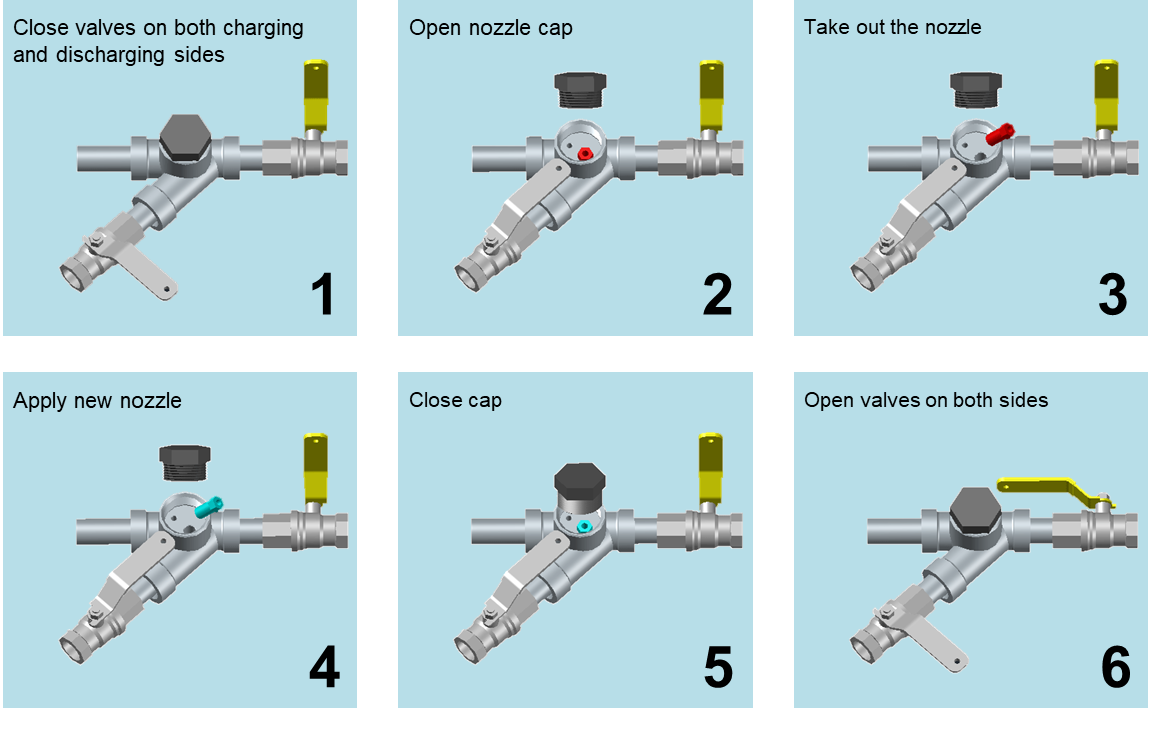

Steps to Change the Nozzle

Change the nozzle just by opening nozzle cap. Quick and easy change without stopping the system

Superior Tolerance and Easy Maintenance

Superior Tolerance

Superior tolerance as there is no moving part

Simple mechanical design with low parts count

Flash steam is less likely to affect the narrowest part, as it is located beyond the tunnel part

Easy Maintenance

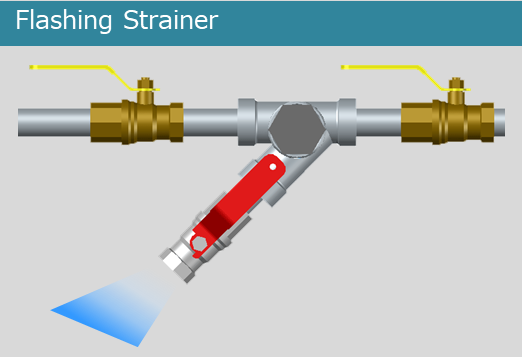

Strainer is narrower than the nozzle pore size, and therefore there will be no

Strainer cleaning can easily flash out pipe scale

Variety of Nozzle Types and Customization

Accommodate Small to Extra Large

27 Standard Nozzles and customized nozzles to accommodate various flow volume

Main body size also has large diameter specifications (e.g. 100A) . Flexible design to accommodate various flange face, pressure specification, etc.

Patent Information on ST Nozzle Type Steam Trap

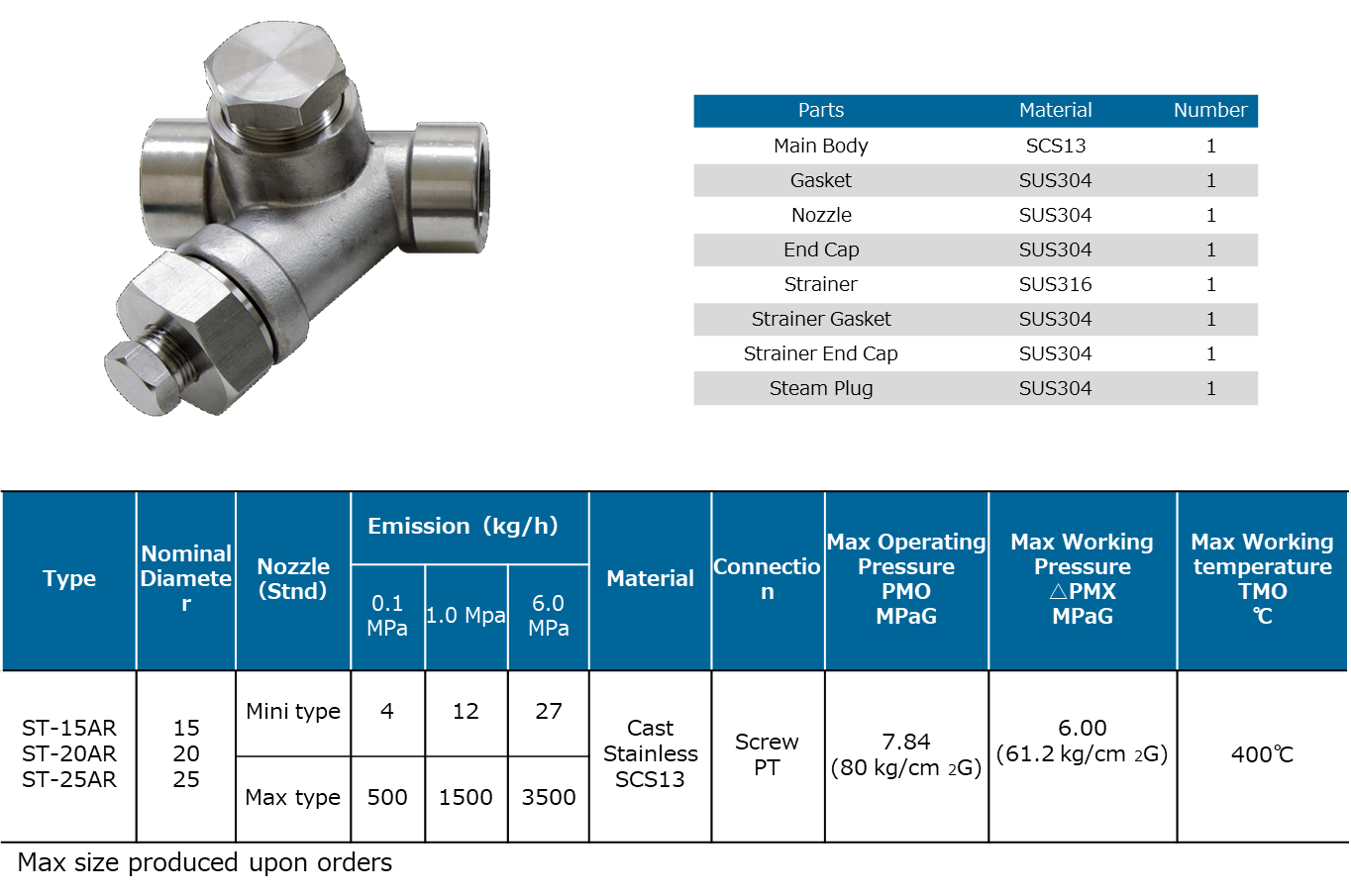

ST Nozzle Type Steam Trap Product Information

Sample Clients of ST Nozzle Type Steam Trap

Ohji Imaging Media

Okamoto Manufacturing

Kansai Beat Sugar

Kibun Foods

Coca Cola West Products

Komica Minolta

Sunstar

Suntory Products

Sanwa Oil

Showa Denko

Shimaya

Sugai Chemical

Sentral Glass Fiber

Sony Semi-conductors

Pacific Sugars

Dai-ichi Kogyo Pharmaceutical

Daido Chemical

Tonen General Oil

Tokyo Thermo Supply

Tomoku

Toray Co Ltd

Nihon Beat Sugar

Nichiban

Nisshin York

Fuji Oil

Shinki Wool

Hokushin

Maruha Nichiro Foods

Meiji

Meiwa Rubber

Yutaka Foods

LG Chem, Ltd.

And Many others